Product Description

Description

The SC8400 submersible velocity sensor is based on the principle of Doppler Effect; it exploits the latest IDSR (Intelligent Doppler Signal Recognition) technology and innovative engineering design. It outputs velocity value by employing the frequency shift between a transmitting ultrasonic wave and its echo caused by suspended particles or gas bubbles (discontinuities) in motion. The sensing elements are Doppler ultrasound twin 1 MHz piezoelectric crystals. The built-in electronic unit performs velocity calculation and outputs digital signal to a receiver like the GDC. The receiver combines with level signal of a known flume cross section to provide corresponding Area/Velocity flow measurement for open channel and non-full pipe application without primary device. SC8400 measures average velocity directly, no more tedious flow profiling work, and significantly reduces the cost of installation and operation for industrial and municipal wastewater pipeline applications provided that the liquid contains at least 50ppm with suspended solids larger than 30 micrometers.

Specification

| Principle | Doppler ultrasound Twin 1 MHz piezoelectric crystals |

| Accuracy | For flows at 1 ft/s (0.30m/s) or greater to + 2 % of velocity reading |

| For Reynolds #’s above 100,000 depending on fluid conditions. To + 5% of velocity reading for Reynolds #’s 10,000 -100,000 (3:1 any range approximately) depending on fluid conditions. Linearity and repeatability to + 0.5% under the same pumping conditions. | |

| Flow Range | 0.3 to 33 ft/s (0.1 to 10 m/s) liquids.50 parts per million (PPM) of a minimum of 30 micron size suspended solids, turbulence or bubbles to ensure accurate, repeatable flow measurement. |

| Temperature | -40 to 122°F (-40 to 50°C) |

| Power Supply | 24 VDC (18 to 36 VDC) by GDC |

| Interface | RS485 Modbus RTU |

Feature

- Easy installation and fast setup with no velocity calibration required.

- Completely sealed sensor withstands submergence and prolonged surcharge conditions.

- Advanced, ultrasonic 1 MHz Doppler technology avoids signal dropouts and ensures high levels of measurement accuracy even in low flow, reversed flow, full pipe and relatively clean water conditions.

- Signal auto-correlation detection and processing technology significantly reduces the noise caused by interference, which improves anti-jamming capability of the instrument.

- RS485 with Modbus RTU protocol.

- Fully compatible with ViewTM for easy setup and data logging.

- POM Housing, Optional SS 316L.

Application

- Flow rate / cross-sectional area flow meter

- With Doppler velocity sensor and ultrasonic level sensor used for sewage pipelines such as non-full pipe or open channel without primary device.

- Portable instrument with Doppler velocity sensor used for river course and sewage pipelines.

Dimesion

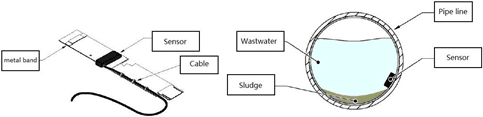

Installation